Dry rooms and anhydrous rooms

A dry room is generally a clean room in which the atmosphere is controlled in temperature and humidity, with a relative humidity of less than 20%. When this level is less than 2%, the term ‘anhydrous room’ is used.

What is a clean room?

Clean rooms are environments with controlled contamination. They are enclosed areas designed for manufacturing, assembling or handling products that are sensitive to particles, humidity or temperature variations. The main objective is to minimise the introduction, generation and retention of particles in the air and on surfaces. The purpose of a clean room is to provide the cleanest possible area, by minimising the presence of particles, bacteria or humidity that could contaminate products.

Clean rooms are used in the pharmaceutical industry, the manufacture of medical equipment, powders, and in electronics for semiconductor production, as well as in the research sector. They guarantee an optimal production environment that meets strict quality requirements.

Current regulations impose strict protocols. Production operators work in full body protective suits, including overboots, gloves, hairnets or hoods, and safety goggles, to ensure perfect hygiene. In some cases, the design of a clean room is required by the client’s technical specification itself, particularly for the production of preclinical batches, research and development, or the manufacture of small series packaged in vials.

Another common constraint is the lack of space in existing industrial facilities. This requires a bespoke design and adaptation of equipment, especially for the integration of high-performance dehumidification solutions into environments that are sometimes confined.

Why control humidity in a clean room?

Controlling humidity in a clean room is essential. Excessive humidity can lead to condensation, boost bacterial growth, alter product quality (particularly powders or electronic components) and is responsible for non-compliance in industrial processes.

Some regulations even require strict humidity control. For instance, the ANSM (the French National Agency for Medicines and Health Products Safety) recommends a humidity level of 30% for some specific pharmaceutical manufacturing processes. Additionally, many clients’ technical specifications demand this level of quality for the development of active ingredients.

Temperature and humidity control

Whether it’s in the chemical, pharmaceutical, food processing or electronics industry, at certain stages of the manufacturing process it is essential to maintain a low relative humidity in production or packaging clean rooms. DESSICA systems make it possible to achieve the required temperature, humidity or dust level conditions in these dry rooms.

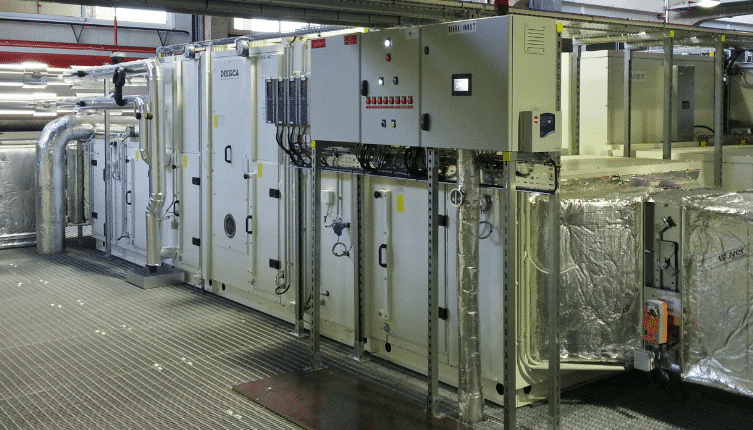

Dessica equipment

Manufacturing, especially of electric car batteries, requires atmospheres with very low humidity (RH between 0.5 and 2%, or dew points between -30°C and -45°C). DESSICA has developed special very high efficiency equipment (dry air down to -65°C dew point) that is also highly impermeable to both air and water vapour for these anhydrous rooms.

Humidity control in clean rooms: solutions are designed to meet industrial requirements

Industrial air dryers play a crucial role in maintaining controlled humidity and temperature conditions in clean rooms, in accordance with strict standards (such as ISO 14644-1). This equipment makes it possible to maintain dry atmospheres, reaching dew points as low as –65°C, while ensuring optimal airtightness against both air and water vapour.

DESSICA has worked with organisations such as Dior for the air treatment of a clean room used for packaging makeup powders, and with the CNRS (National Centre for Scientific Research) in Amiens to maintain a dry atmosphere with a low dew point.

The systems can be installed upstream of air-handling units and maintain constant humidity levels in clean rooms, ensuring suitable environments for sensitive processes.

Industrial air dryers are specifically designed to control and regulate humidity in clean rooms with controlled atmospheres. The DP range of air dryers for industrial processes has been purposely developed to meet the needs of production and packaging environments, as well as drying processes. The professional DP air dryers feature a robust stainless-steel body, both inside and out, and incorporate a high-performance silica gel desiccant wheel, ensuring efficient moisture adsorption.

Controlling humidity offers numerous advantages, including:

• Increasing productivity

• Limiting bacterial growth and airborne contamination

• Preserving the quality of hygroscopic materials

• Ensuring powder flowability and preventing clogging

• Eliminating condensation issues and improving the quality of finished products

• Reducing losses due to sticking and clogging

• Improving hygiene, safety, and working conditions

How can humidity be effectively reduced?

Managing humidity in a clean room generally relies on two main types of equipment:

- The air-handling unit (AHU): it provides overall control of temperature, humidity and pressure. However, an AHU on its own is not enough to reduce humidity to below 80%.

- The industrial air dehumidifier: essential for reaching lower humidity levels, from 50% down to 30% relative humidity (and even lower). It ensures optimal conditions, even when facing space constraints or specific client requirements.

DESSICA designs bespoke solutions adapted to the constraints of clean rooms, regardless of project complexity, whether for clinical batch production, R&D, pharmaceutical manufacturing, or electronics production.

Industrial air dryers are specifically designed to control and regulate humidity in clean rooms with controlled atmospheres. The DP range of air dryers for industrial processes is specially engineered to meet the needs of production and packaging environments, as well as drying processes. Professional DP air dryers feature a robust stainless-steel construction, both inside and out, and incorporate a high-performance silica gel desiccant wheel, ensuring efficient moisture adsorption.

Why choose DESSICA dehumidifiers?

DESSICA industrial dehumidifiers are designed to operate 24 hours a day, 7 days a week, all year round. They are reliable, low-maintenance and guarantee stable control, limiting the risk of breakdowns or production stoppages.

Our in-house technical team precisely configures each installation to compensate for climatic variations, particularly when faced with extreme weather events (storms, heatwaves, increased humidity).

• Anticipate your needs: installing an air dehumidifier helps quickly respond to your customers’ requirements, reduce production start-up times, and avoid non-conformities.

• Comprehensive service: DESSICA offers maintenance contracts for all types of dehumidifiers, regardless of their brand.

By choosing DESSICA, you benefit from the expertise of a company renowned for its rigour, reliability, and professional guidance. Our teams will follow your requirements and design a suitable solution for your production constraints and your customers’ requirements.