Controlling air humidity is a crucial issue in many industrial environments. Excess moisture, condensation or mould can compromise product quality, damage equipment or disrupt processes. This is where air dehumidifiers can help. They are an effective solution for controlling humidity levels, ensuring equipment performance and guaranteeing optimal production conditions. In this article, you will discover how an industrial dehumidifier works, particularly models using desiccant technology, which are highly regarded for their effectiveness in demanding environments.

There are two types of industrial air dehumidifiers: desiccant wheel dehumidifiers and refrigerant dehumidifiers (using condensation). The main difference lies in how they operate.

How Dessica desiccant wheel air dehumidifiers work

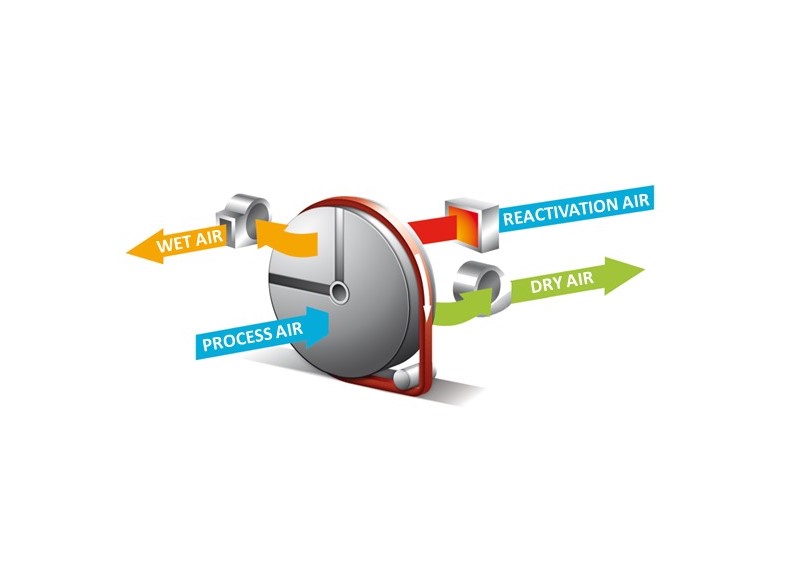

DESSICA desiccant wheel air dehumidifiers (or adsorption dehumidifiers) are designed to maintain a constant, controlled humidity level in sensitive industrial environments. They operate using adsorption technology, which involves a rotating wheel coated with silica gel, a highly effective desiccant material. Humid air (labelled ‘air to be dehumidified’ in the diagram) is drawn into the dehumidifier and passes through the wheel, where the moisture is captured by the silica gel. The treated air is dry and can be directed to the production area or industrial process requiring a controlled environment.

At the same time, a second stream of air called regeneration air, is heated and directed through one of the areas of the wheel (approximately a quarter of its surface) to remove moisture retained in the silica gel. This cycle allows for continuous regeneration of the wheel, ensuring continuous operation and consistent performance, even at low temperatures or with very humid air. This technology, free from refrigerant fluids, offers a sustainable, energy-efficient and environmentally friendly solution. DESSICA equipment can be easily integrated into various sectors, including agri-food, pharmaceutical, electronics and storage, to preserve product quality and guarantee process safety.

Video: How industrial air dryers work

Our explanatory video makes it easier to understand how industrial air dryer works, adding visual elements to the technical explanations.

Desiccant air dehumidifiers

How condensation dehumidifiers work

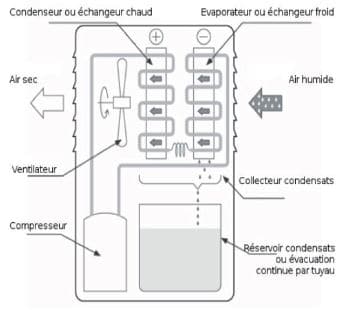

Condensation dehumidifiers are designed to extract moisture from the air, particularly in environments where the temperature is moderate to high. The way this type of dehumidifier operates is simple and effective: humid air is sucked in by a fan and directed to a heat exchanger, where it is cooled below its dew point. The water vapour in the air condenses into droplets, which are collected in a tank or drained away via a drainage system (wastewater evacuation). The now dry air is then reheated before being blown back into the room. This technology is ideal for maintaining a controlled humidity level in buildings, storage areas, technical rooms or industrial processes requiring stable air conditions. DESSICA fixed and ducted dehumidifiers are robust, low energy and can adapt to the constraints of each environment. By opting for a condensation dehumidification system, manufacturers are guaranteed a reliable, sustainable and efficient solution to protect their facilities, improve production quality and prevent moisture-related damage.

Refrigerant air dehumidifiers

Difference between condensation dehumidifiers and adsorption dehumidifiers

Apart from the much higher cost of the latter, the main difference between a condensation dehumidifier and an adsorption (desiccant wheel) dehumidifier is the rise in temperature: approximately +2°C with a condensation dehumidifier versus +15 to 20°C with an adsorption dehumidifier.

Desiccant dehumidifiers are preferred when very low humidity levels are required (below 30% relative humidity), especially at low temperatures.

Condensation dehumidifiers are effective in an operating range between +7°C and +35°C, with relative humidity between 35% and 95%.

Adsorption dehumidifiers are designed to operate in environments where the temperature varies between -15°C and +40°C. When it comes to achieving low humidity levels, desiccant air dehumidifiers are more energy efficient than condensation dehumidifiers.

On a final note, understanding how dehumidifiers work is essential for choosing the technology best suited to your industrial needs. Whether you choose Dessica desiccant dehumidifiers, designed for environments requiring very low humidity, or condensation dehumidifiers, which are more effective in moderate humidity and temperature conditions, each solution has its advantages depending on the constraints of the process. It is also important to clearly differentiate between condensation dehumidifiers and adsorption systems, in order to choose the most efficient equipment for your objectives in terms of air quality, energy consumption and climate control. At Dessica, we support you in this process with customised, reliable and sustainable solutions.